Pattern Grading Explained: From Sample Size to Full Range

- thecottonkraftco

- Nov 30, 2025

- 15 min read

Updated: Dec 24, 2025

You've perfected your sample garment. The fit is flawless on your fit model. Your design looks exactly as you envisioned. But now comes a critical question: how do you create the same garment in multiple sizes while maintaining that perfect fit and proportion across your entire size range?

The answer is pattern grading—one of the most important technical processes in garment production, yet often the least understood by fashion entrepreneurs and emerging brands.

Poor grading destroys otherwise excellent designs. A dress that fits beautifully in size M becomes unwearable in XS or XXL if graded incorrectly. Disproportionate sizing leads to customer returns, negative reviews, and damage to your brand reputation. Conversely, excellent pattern grading ensures every customer—regardless of size—experiences the same great fit that you achieved in your sample.

This comprehensive size grading guide explains everything you need to know about pattern grading: what it is, why it matters, how it works, different grading methods, common mistakes to avoid, and how to ensure your patterns are graded correctly.

Whether you're a fashion startup developing your first size range or an established brand looking to improve sizing consistency, understanding how to grade patterns is essential for product success.

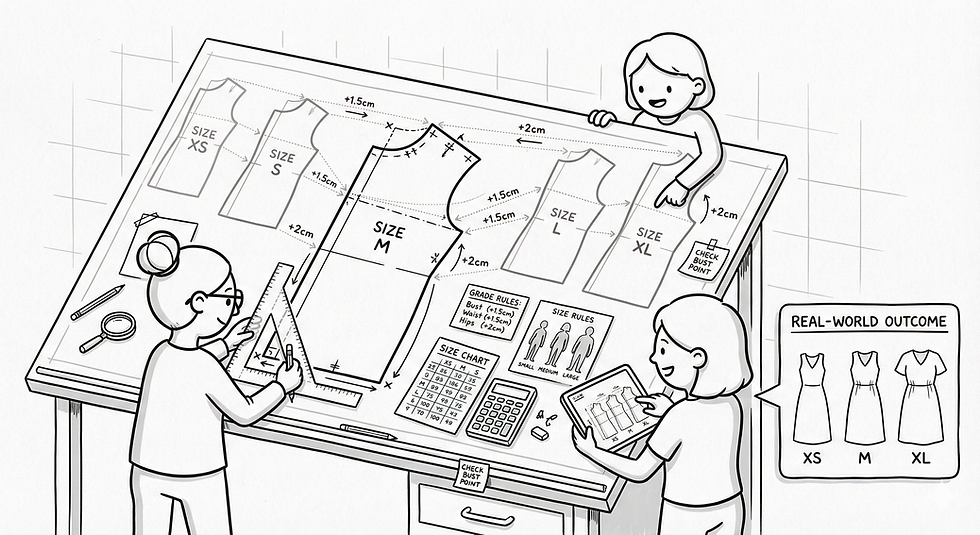

What is Pattern Grading?

Pattern grading is the technical process of proportionally increasing or decreasing a base pattern to create a complete range of sizes. It's the systematic method of taking your perfected sample-size pattern and mathematically adjusting it to fit different body sizes while maintaining the design's original proportions, style lines, and intended fit.

The Core Concept

Think of pattern grading like this: imagine you have a photograph that looks perfect at 8x10 inches. If you simply enlarge it to 16x20 by doubling all dimensions equally, it remains proportionate. But human bodies don't work that way—they don't scale proportionally in all directions simultaneously.

When a person goes from size S to size XL, their bust might increase by 4 inches, but their shoulder width might only increase by 1 inch. Their waist circumference increases, but their arm length might stay nearly the same. Pattern grading accounts for these non-uniform changes through grade rules—specific measurement increases or decreases at strategic points on the pattern.

Beyond Simple Scaling

Many beginners think grading means just making patterns bigger or smaller uniformly. This creates distorted garments:

Wrong Approach: Enlarge the entire pattern by 20% Result: A size L where everything is bigger—sleeve too long, neck too wide, waist too loose—garment looks and fits wrong

Correct Approach: Apply specific grade increments at strategic points based on body measurement standards Result: A size L where dimensions increase appropriately—bust and hip are larger but sleeve length, neck width, and shoulder slope remain proportionate to the body

What Gets Graded

In pattern grading, different areas of patterns receive different treatment:

Circumferences (bust, waist, hip): Grade significantly between sizes—typically 2-4 cm (1-1.5 inches) per size

Lengths (torso, sleeve, inseam): Grade minimally or not at all—most bodies don't dramatically change height between clothing sizes

Widths (shoulder, back width): Grade moderately—some increase but less than circumferences

Armholes and Necklines: Grade carefully to maintain proper proportions and comfort

Design Elements (pockets, collars, cuffs): May or may not grade depending on design intent

Understanding what changes and what stays constant is fundamental to proper pattern grading.

Why Pattern Grading Matters

Accurate pattern grading directly impacts your business success:

Customer Satisfaction and Fit

Consistent Fit Experience: Customers expect the same great fit regardless of which size they order. Poor grading means some sizes fit well while others don't—creating disappointed customers.

Reduced Returns: Fit-related returns are expensive. Industry data shows 30-40% of online fashion returns are due to sizing and fit issues. Proper grading significantly reduces this.

Positive Reviews: Consistent sizing across your range generates positive feedback: "True to size!" "Finally a brand where I know my size!" These reviews drive sales.

Brand Loyalty: When customers find a brand with reliable, consistent sizing, they become repeat buyers.

Inclusive Sizing and Market Reach

Expanded Market: Offering XS-3XL instead of just S-L can increase your addressable market by 60-80%.

Inclusive Brand Image: Modern consumers increasingly expect size inclusivity. Brands offering limited size ranges face criticism and lose potential customers.

Demographic Reach: Different regions and demographics have different average body sizes. Comprehensive size ranges allow you to serve diverse markets.

Production Efficiency

Manufacturer Confidence: Well-graded patterns reduce production issues. Manufacturers can cut and sew all sizes efficiently without constant troubleshooting.

Reduced Sampling: Accurate grading means fewer fit samples needed across size ranges—you can validate base size thoroughly and trust the graded sizes.

Consistent Quality: Proper grading ensures construction details work correctly in all sizes—pockets are proportionate, buttonholes are properly placed, design elements scale appropriately.

Cost Management

Fabric Efficiency: Accurate grading enables precise fabric consumption calculations for all sizes, improving ordering accuracy and reducing waste.

Reduced Errors: Grading mistakes discovered in production are expensive to fix—patterns must be corrected, new samples made, potentially entire production runs remade.

Faster Time to Market: Professional grading gets sizing right the first time, eliminating delays from size-related issues during production.

Understanding Grade Rules

Grade rules are the mathematical foundation of pattern grading—they define exactly how much to add or subtract at each point on a pattern when moving between sizes.

What Are Grade Rules?

A grade rule specifies:

Location: The specific point on the pattern (e.g., bust point, waist side seam, hem center)

Direction: X-axis (horizontal) and Y-axis (vertical) movement

Amount: How many millimeters or inches to move in each direction for each size change

Example Grade Rule for Bust Point:

Between sizes: +12mm X-axis (outward), +3mm Y-axis (downward)

This moves the bust point slightly outward and down as size increases

Standard vs. Custom Grade Rules

Standard Grade Rules: Industry-established grade increments based on standard body measurement charts:

US standard sizing uses different grade rules than UK or EU sizing

Menswear has different grade rules than womenswear

Children's wear uses different rules accounting for growth patterns

Custom Grade Rules: Developed specifically for your brand's target fit:

May adjust standard rules to match your fit model or target demographic

Can be tailored for specific body types (petite, tall, plus-size, athletic)

Reflect your brand's unique fit philosophy and aesthetic

Typical Grade Increments

Womenswear Standard Grading (per size):

Bust: 4-5 cm (1.5-2 inches)

Waist: 5-6 cm (2-2.5 inches)

Hip: 5 cm (2 inches)

Shoulder width: 1 cm (0.4 inches)

Armhole depth: 1.5 cm (0.6 inches)

Back width: 1 cm (0.4 inches)

Body length: 0-1 cm (0-0.4 inches)

Sleeve length: 0-0.5 cm (0-0.2 inches)

Menswear Standard Grading (per size):

Chest: 5 cm (2 inches)

Waist: 5 cm (2 inches)

Neck: 1.25 cm (0.5 inches)

Shoulder: 1.25 cm (0.5 inches)

Sleeve length: 1.25 cm (0.5 inches)

Torso length: 0.5 cm (0.2 inches)

These are starting points—actual grade rules are more complex and detailed, with different increments at different points to maintain proportions.

How Pattern Grading Works: Methods Explained

There are three primary methods for how to grade patterns:

Method 1: Manual Pattern Grading

Traditional hand-grading using physical tools:

Process:

Trace the base size pattern onto new paper

Using grade rules, measure and mark new points for the next size

Connect new points with French curves and rulers to create new pattern lines

Add or remove increments at specific pattern locations

Repeat for each size in the range

Tools Required:

Large pattern paper

Grading rulers with grade increment marks

French curves and hip curves

Measuring tapes and rulers

Pattern weights

Pencils and markers

Advantages:

No software required

Pattern maker has direct control

Good for learning grading fundamentals

Works for small size ranges or one-off custom grading

Disadvantages:

Extremely time-consuming (2-4 hours per size per pattern)

Prone to human error in measurements

Difficult to maintain perfect consistency

Hard to modify if grade rules need adjustment

Physical storage of multiple size patterns required

Best For: Educational purposes, very small boutique operations, or situations where digital tools aren't available.

Method 2: Digital CAD Pattern Grading

Computer-aided grading using professional software:

Process:

Base pattern is created or imported into CAD software

Grade rules are established in the software (one time setup)

Software automatically applies grade rules to all pattern points

All sizes in the range are generated simultaneously

Pattern maker reviews graded nest for accuracy

Adjustments made if needed and all sizes update automatically

Software Used:

Gerber AccuMark

Lectra Modaris

Optitex

StyleCAD

Other professional CAD systems

Advantages:

Extremely fast—entire size range graded in minutes

Mathematical precision—perfect consistency

Easy to modify and regenerate if grade rules change

Digital storage—no physical space required

Visual nest display shows all sizes overlaid for review

Direct integration with cutting and production systems

Disadvantages:

Requires expensive software (₹50,000-₹2,00,000+ annually)

Learning curve for software operation

Initial grade rule setup requires expertise

Hardware requirements (computers, large monitors)

Best For: Professional pattern making services, brands with ongoing grading needs, manufacturers, and anyone requiring production-scale grading.

Method 3: Parametric or Algorithmic Grading

Advanced automated grading based on body measurement input:

Process:

Create parametric pattern that's measurement-driven

Input body measurements for each size

Software automatically generates patterns for each size

Each size is mathematically calculated from measurements

Patterns adapt automatically to different body types

Technology:

Advanced features in CAD systems

Specialized parametric design software

Made-to-measure automation systems

AI-assisted pattern generation

Advantages:

Highly flexible—can create any size from measurements

Enables true made-to-measure production

Perfect for custom sizing or inclusive size ranges

Once set up, generates unlimited sizes instantly

Can accommodate different body proportions automatically

Disadvantages:

Complex initial setup requiring expert pattern engineering

Most sophisticated software required

Requires deep understanding of pattern construction

Not all garment types work well with parametric approach

Best For: Made-to-measure businesses, brands offering extensive size customization, advanced production operations, and future-forward fashion technology companies.

The Pattern Grading Process Step by Step

Here's how professional pattern grading works using the modern CAD method:

Step 1: Perfect the Base Size Pattern

Critical First Step: Grading multiplies whatever exists in your base pattern—including errors. You must perfect your base size before grading.

Base Size Selection: Most brands choose size M or L as their base pattern (the size most thoroughly tested and fitted).

Sample Fitting: Multiple fit sessions ensuring the base size fits perfectly with correct ease, proper balance, and intended design proportions.

Pattern Refinement: Adjust base patterns based on fit session feedback until sample is approved.

Documentation: Record all specifications, ease allowances, and design intent for reference during grading.

Step 2: Establish Grade Rules

Measurement Standards: Determine target body measurements for each size based on:

Industry standard size charts (ASTM, ISO, or regional standards)

Your brand's custom sizing philosophy

Target market demographic data

Fit testing across size range

Create Grade Rule Table: Document grade increments between sizes:

Bust/chest grade: +/- X cm per size

Waist grade: +/- X cm per size

Hip grade: +/- X cm per size

Other critical measurements

Identify Grade Points: Mark specific locations on patterns where grade rules apply—typically 20-40+ grade points per garment depending on complexity.

Input Rules into CAD: Enter all grade rule data into pattern making software, creating a grading library.

Step 3: Apply Grading to Base Pattern

Import Base Pattern: Load perfected base size pattern into CAD grading module.

Assign Grade Rules: Apply appropriate grade rules to each pattern piece and each grade point.

Generate Size Range: Execute grading operation—software calculates all sizes simultaneously.

Review Graded Nest: Examine all pattern sizes overlaid to verify smooth, logical progression without anomalies.

Step 4: Validate Graded Patterns

Visual Inspection: Review each graded size for:

Smooth curves without irregularities

Proper proportions maintained

Design elements scaling appropriately

All pattern markings present and correctly positioned

Measurement Check: Verify critical measurements in each graded size match target specifications:

Measure key dimensions on graded patterns

Compare to size chart targets

Ensure grade increments are consistent

Proportion Analysis: Check that design proportions work across all sizes:

Pocket placement appropriate for each size

Button spacing proportionate

Design details scaled correctly

Style lines maintain intended aesthetic

Step 5: Physical Validation (Recommended)

Select Validation Sizes: Choose 2-3 sizes beyond base for physical testing—typically smallest, largest, and one mid-range size.

Produce Test Samples: Cut and sew samples in validation sizes.

Fit Testing: Fit samples on appropriate body types or fit models.

Identify Issues: Note any fit problems, proportion issues, or construction challenges in graded sizes.

Adjust Grade Rules: If issues found, modify grade rules and regenerate all sizes.

Re-test: Produce new samples with adjusted grading and re-validate.

Step 6: Finalize and Document

Lock Grade Rules: Once validated, save final grade rule library for future use and consistency.

Generate All Production Files: Create production-ready patterns for all sizes with complete markings, seam allowances, and notations.

Create Size Documentation: Produce comprehensive size charts, grading specifications, and measurement documents.

Archive: Store all pattern files and grading data systematically for future access and modifications.

Common Pattern Grading Mistakes and How to Avoid Them

Even experienced pattern makers can make these pattern grading errors:

Mistake 1: Grading Lengths Excessively

Error: Adding significant length grade between sizes, assuming taller people wear larger sizes.

Reality: Height doesn't correlate perfectly with size. A 5'10" person might wear size S while a 5'4" person wears size XL.

Solution: Grade body lengths minimally (0-1 cm per size) and offer separate petite/regular/tall length options if needed.

Mistake 2: Uniform Proportional Grading

Error: Increasing all pattern dimensions by the same percentage—treating the body like a balloon that inflates uniformly.

Reality: Bodies increase disproportionately—torso circumferences change more than shoulder widths, which change more than lengths.

Solution: Use proper grade rules with different increments for different body areas based on anthropometric data.

Mistake 3: Grading Design Details Incorrectly

Error: Scaling pockets, collars, cuffs, and trims proportionally with the garment size.

Reality: Some design elements should remain constant across sizes (button size, trim width) while others grade partially.

Solution: Decide design element grading case-by-case—will a pocket look better staying the same size or scaling with the garment?

Mistake 4: Ignoring Ease Distribution

Error: Grading pattern pieces without considering how wearing ease should distribute across sizes.

Reality: Larger sizes often need slightly more ease percentage-wise for comfort and movement, while smaller sizes can be more fitted.

Solution: Adjust ease allowances as part of grade rules, particularly for fitted garments and structured styles.

Mistake 5: Neglecting Balance and Fit Lines

Error: Grading without maintaining critical balance points like shoulder slope angle, armhole shape, or waist curve.

Reality: These fit-critical elements need careful grading to maintain proper garment balance on the body across sizes.

Solution: Grade rules must account for maintaining proper angles, curves, and proportions that affect garment hang and fit.

Mistake 6: Insufficient Validation

Error: Grading all sizes from base pattern without physical testing across size range.

Reality: What works in theory doesn't always work on actual bodies. Issues often appear in extreme sizes (very small or very large).

Solution: Always validate grading with physical samples in at least 2-3 sizes beyond your base before production.

Mistake 7: Copy-Paste from Standards Without Adjustment

Error: Using standard grade rules directly from industry charts without considering your specific design, fit, or target market.

Reality: Standard grade rules are starting points, not universal solutions. Each brand's fit philosophy and target customer requires customization.

Solution: Start with standard rules but adjust based on your fit model, customer feedback, and brand positioning (more fitted vs. relaxed, etc.).

Pattern Grading for Different Garment Categories

Different garment types require different pattern grading approaches:

Woven vs. Knit Garments

Woven Garments (shirts, dresses, structured jackets):

More critical grading precision required

Less room for error—no stretch to forgive mistakes

Focus on accurate circumferences and proper ease

Armholes, necklines particularly critical

Knit Garments (T-shirts, jersey dresses, activewear):

Stretch provides some fit forgiveness

Grading can be slightly broader (fewer intermediate sizes)

Must account for fabric stretch percentage in grade rules

Negative ease possible in fitted styles

Fitted vs. Relaxed Styles

Fitted Garments:

Require more precise grading

May need more intermediate sizes for better fit across range

Critical grade points include bust, waist, hip shaping

Smaller grade increments often appropriate

Relaxed/Oversized Garments:

More forgiving grading tolerances

Fewer sizes may cover wider range of bodies

Focus on overall silhouette maintenance across sizes

Design proportions more important than precise fit

Structured vs. Unstructured

Structured Garments (tailored jackets, coats):

Complex grading due to internal construction

Interfacing and lining must grade with shell

Shoulder pads and structural elements need size-specific scaling

Requires expert grading knowledge

Unstructured Garments (flowing dresses, soft tops):

Simpler grading with fewer critical fit points

Drape and proportion primary concerns

More flexible regarding exact measurements

Specialized Categories

Maternity Wear: Unique grading accommodating pregnancy body changes across trimesters

Childrenswear: Different grade rules based on child development and growth patterns

Plus-Size: Modified grade rules addressing different body proportions in extended sizes

Performance/Athletic: Grading must maintain performance features (compression, support) across sizes

Professional Pattern Grading Services vs. DIY

Should you grade patterns yourself or use professional services?

When to Use Professional Pattern Grading Services

You Should Outsource If:

✅ Limited Technical Knowledge: You're not a trained pattern maker and don't know proper grading methods

✅ No CAD Software: You don't own professional grading software (₹50,000-₹2,00,000 investment)

✅ Time Constraints: Your time is better spent on design, marketing, and business development

✅ Quality Critical: Your brand reputation depends on consistent, reliable sizing

✅ Multiple Categories: You design diverse garment types requiring different grading expertise

✅ Production Scale: You're producing in quantities where grading errors would be costly

✅ Complex Garments: Structured, fitted, or technically complex styles requiring expert grading

When DIY Grading Might Work

Consider DIY Only If:

✅ Pattern Making Training: You have professional pattern making education and experience

✅ Simple Garments: Very basic, unstructured styles with forgiving fit (like some children's wear or loungewear)

✅ Tiny Scale: Producing very small quantities (under 50 pieces) where professional investment seems disproportionate

✅ Learning Goal: Your objective is education rather than production efficiency

✅ Software Access: You have access to CAD grading software and know how to use it

Warning: Poor grading is expensive—fit issues, returns, and reputation damage cost far more than professional grading services.

COKAA's Pattern Grading Services

COKAA provides professional pattern grading services for fashion brands of all sizes:

Our Grading Expertise

Experienced Grading Specialists: Pattern engineers with 15+ years grading diverse garment categories across all sizing systems.

Industry-Standard CAD: We use Gerber AccuMark, Lectra Modaris, and Optitex for mathematical precision and consistency.

Custom Grade Rules: We develop brand-specific grade rules based on your fit philosophy and target market.

Comprehensive Validation: Physical sample validation included in extended grading projects to ensure accuracy.

Our Grading Services Include

Standard Size Grading: Grade your base pattern across any size range using industry-standard or custom rules.

Custom Grade Rule Development: Create unique grading specifications for your brand's signature fit.

Grading Validation: Physical sample testing across size range to verify grading accuracy.

Grade Rule Adjustment: Refine grading based on fit testing feedback until all sizes fit perfectly.

Multi-Size Nesting: Provide all sizes overlaid for visual verification and comparison.

Size Chart Creation: Generate accurate size charts based on your graded patterns.

International Sizing: Grade patterns for different regional size standards (US, UK, EU, Asian sizing).

Size Ranges We Handle

Standard Ranges: XS-XL, XS-XXL, XS-3XL

Extended Plus Sizing: 1X-5X, sizes 14-32

Petite and Tall: Length-adjusted grading for different heights

Childrenswear: Age-based sizing (2T-14, infant-teen)

Menswear: Alpha sizing (S-XXL) or numeric (36-52)

Custom Ranges: Any size range your brand requires

Our Process

Step 1: Receive your base size pattern and specifications

Step 2: Discuss grade rules—use standards or develop custom rules

Step 3: Grade patterns using professional CAD software

Step 4: Provide graded nest showing all sizes for review

Step 5: Deliver production files for all sizes in required formats

Step 6: Optional validation samples for fit testing

Pricing

Standard Grading (using established grade rules):

Per size per pattern: ₹300-₹800

Complete size range (5-8 sizes): ₹2,500-₹6,000 per style

Custom Grade Rule Development:

₹5,000-₹15,000 per garment category (one-time investment)

Includes validation samples and refinement

Validation Sampling:

₹2,000-₹5,000 per size (if client requests physical samples)

Volume Discounts: 15-25% discount for collections (10+ styles)

Why Choose COKAA for Pattern Grading

✅ Mathematical Precision: CAD grading ensures perfect consistency across all sizes

✅ Expert Review: Human pattern makers verify all grading for logic and proportions

✅ Fast Turnaround: Most grading projects completed in 3-5 business days

✅ Affordable Rates: Professional quality at startup-friendly prices

✅ Flexible Service: Grade one pattern or entire collections

✅ Complete Files: Receive all sizes in production-ready formats (DXF, PLT, PDF)

✅ Ongoing Support: Available for questions and adjustments during production

Pattern Grading Best Practices

Follow these guidelines for optimal pattern grading results:

Before Grading

✅ Perfect Your Base Size: Don't grade until your base pattern fits flawlessly

✅ Choose Right Base Size: Select the size most representative of your target market (usually M or L)

✅ Document Everything: Record all measurements, ease allowances, and fit specifications

✅ Select Appropriate Grade Rules: Choose rules that match your fit philosophy and target body type

During Grading

✅ Maintain Proportions: Ensure design elements scale appropriately

✅ Review Graded Nest: Visual inspection of all sizes overlaid catches errors

✅ Check Critical Measurements: Verify that graded sizes hit target measurements

✅ Test Extreme Sizes: Pay special attention to smallest and largest sizes where issues often appear

After Grading

✅ Validate with Samples: Produce physical samples in multiple sizes for fit testing

✅ Gather Feedback: Test on appropriate body types across size range

✅ Adjust as Needed: Refine grade rules based on validation results

✅ Document Final Rules: Save approved grade rules for consistency in future collections

Ongoing

✅ Monitor Customer Feedback: Track return reasons and fit complaints by size

✅ Update Size Charts: Ensure size charts accurately reflect your graded patterns

✅ Maintain Consistency: Use the same grade rules across collections for brand size consistency

✅ Review Periodically: Update grade rules if target market or fit philosophy evolves

The Future of Pattern Grading

Pattern grading continues to evolve with technology:

Emerging Trends

AI-Assisted Grading: Machine learning analyzing body scan data to optimize grade rules automatically

Body Scan Integration: Direct grading from 3D body scan databases reflecting actual population measurements

Parametric Grading: Fully automated grading that generates any size from inputted measurements

Inclusive Sizing Tools: Technology specifically designed for extended size grading with different body proportions

Real-Time Customization: Made-to-measure grading enabling true size customization for each customer

Sustainability Focus: Grading optimization that reduces fabric waste across size ranges

What This Means for Brands

Greater Accuracy: Technology will continue improving grading precision

More Inclusivity: Better tools for true size inclusivity across all body types

Faster Development: Grading will become even faster and more automated

Mass Customization: Ability to offer custom sizing at scale becoming practical

Better Data: Customer body data informing improved grading decisions

Conclusion: Grading as Foundation of Great Fit

Pattern grading is where fit promise meets sizing reality. Your sample size might fit perfectly, but without proper grading, your brand can't deliver that perfect fit to all customers across your size range.

Professional pattern grading is not a luxury—it's a necessity for any fashion brand serious about quality, customer satisfaction, and inclusive sizing. The investment in proper grading (whether through professional services or in-house expertise) pays returns through reduced returns, positive reviews, and brand loyalty.

At COKAA, we understand that how to grade patterns properly is both art and science. Our experienced pattern engineers combine technical precision with practical garment knowledge to deliver grading that works—patterns that maintain your design vision while fitting bodies accurately across your entire size range.

Your design deserves to fit everyone beautifully. Professional pattern grading makes that possible.

Ready for professional pattern grading that ensures consistent fit across all sizes? Contact COKAA today for accurate, affordable grading services that support your brand's sizing goals.

Perfect fit. Every size. Every time.

Comments