Custom Pattern Making Services: What to Expect from Professional Bespoke Patterns

- thecottonkraftco

- Jan 8

- 13 min read

Why Custom Pattern Making Services Transform Your Fashion Business

The fashion industry generates over $1.5 trillion annually, yet most brands struggle with the same fundamental challenge: patterns that don't translate their design vision into perfectly fitting, production-ready garments. Off-the-shelf pattern blocks create mediocre fits, standard sizing systems ignore target customer proportions, and generic grading rules produce inconsistent results across size ranges—making professional custom pattern making services not luxury extras but business necessities for brands serious about quality and fit.

At COKAA by JR Corporation, our 20 years of pattern making expertise centers on bespoke pattern development for fashion brands, designers, and manufacturers worldwide. We've created custom patterns for everything from haute couture evening gowns to technical outdoor gear, understanding that successful custom pattern making requires comprehensive understanding of design intent, body proportions, fabric behavior, production requirements, and commercial viability that generic pattern services simply cannot provide.

This comprehensive guide reveals everything about professional custom pattern making services: what you receive, how the process works, timeline expectations, cost considerations, quality standards, and how to evaluate pattern making services. Whether you're launching a new fashion brand, developing a signature collection, or seeking better-fitting products, you'll discover exactly what professional bespoke pattern services deliver and why expertise matters.

Part 1: Understanding Custom Pattern Making Services

Professional custom pattern making creates unique, tailored patterns for specific design requirements.

What Custom Pattern Making Delivers

Bespoke Pattern Development:

Patterns created specifically for your designs

Not modified blocks or adapted templates

Engineered for your target fit and aesthetic

Optimized for your fabric choices

Made-to-Measure Specifications:

Patterns built to exact measurements

Target customer body proportions incorporated

Fit preferences accommodated

Size-specific engineering when needed

Production-Ready Patterns:

Complete pattern sets with all pieces

Graded across full size range

Marked with notations and specifications

Ready for sample making and production

Technical Documentation:

Construction specifications

Measurement charts

Fabric requirements

Assembly instructions

What Makes Patterns "Custom"

Design-Specific Engineering: Every design has unique requirements:

Silhouette and fit intent

Style lines and seaming

Closure systems and details

Fabric characteristics

Target customer body type

Purpose-Built Foundation: Rather than adapting existing blocks:

Created from your specifications

Engineered for intended use

Optimized for manufacturing method

Developed for your quality standards

Iterative Refinement: Professional process includes:

Initial pattern draft

Sample review and fitting

Pattern adjustments

Final perfected pattern

Quality verification

Part 2: The Custom Pattern Making Process

Understanding the workflow helps set appropriate expectations.

Phase 1: Design Consultation and Briefing

Information Gathering: Comprehensive understanding of requirements:

Design sketches or technical flats

Fit intention and silhouette goals

Target customer demographics

Fabric selections and properties

Production method and volume

Budget and timeline constraints

Measurement Specifications: Establishing pattern dimensions:

Target body measurements

Fit preferences (ease allowances)

Critical fit points identified

Proportion considerations

Size range requirements

Technical Discussion: Addressing feasibility and optimization:

Design elements evaluation

Construction method recommendations

Cost-effective alternatives proposed

Potential challenges identified

Timeline realistic assessment

COKAA Approach: Our consultation phase identifies not just what you want, but what you need—sometimes revealing considerations you hadn't anticipated that affect pattern success.

Phase 2: Pattern Drafting and Development

Initial Pattern Creation: First draft development:

Base patterns drafted to specifications

Design elements incorporated

Style lines and seaming placed

Closures and details engineered

Grain lines and notations added

Computer-Aided Pattern Making: Modern technology for precision:

CAD systems for accuracy

Easy modifications and adjustments

Grading preparation

Digital file delivery options

Archival for future production

Technical Considerations: Engineering for performance:

Fabric drape and stretch accommodation

Seam allowance appropriate for construction

Notching for accurate assembly

Balance and hang optimization

Production efficiency considerations

Phase 3: Sample Making and Fit Evaluation

First Sample Production: Pattern validation through garment:

Sample sewn from patterns

Fit on appropriate form or model

Construction feasibility verified

Design intent achievement assessed

Issues identified for correction

Fit Session: Critical evaluation stage:

Try on target body type

Movement and comfort tested

Proportions and balance checked

Design satisfaction confirmed

Adjustment needs documented

Common Adjustments: Typical refinements needed:

Length adjustments (overall or specific areas)

Width modifications (ease changes)

Style line repositioning

Curve adjustments for better fit

Construction sequence improvements

Iteration Process: Refining toward perfection:

Patterns adjusted based on fitting

Second sample if significant changes

Final approval confirmation

Pattern finalization

Documentation completion

Phase 4: Grading and Final Specifications

Size Range Development: Extending patterns across sizes:

Grading rules created

Each size pattern generated

Grade consistency verified

Proportion maintenance checked

Measurement charts developed

Technical Documentation: Complete specifications package:

Construction details

Seam allowances and methods

Notching system explained

Fabric requirements per size

Assembly sequence

Quality standards

Measurement tolerances

File Delivery: Formats appropriate for use:

Digital pattern files (DXF, AAMA, etc.)

PDF technical packages

Printed pattern sets if requested

Measurement charts

Specification sheets

Part 3: Types of Custom Pattern Making Services

Different projects require different approaches.

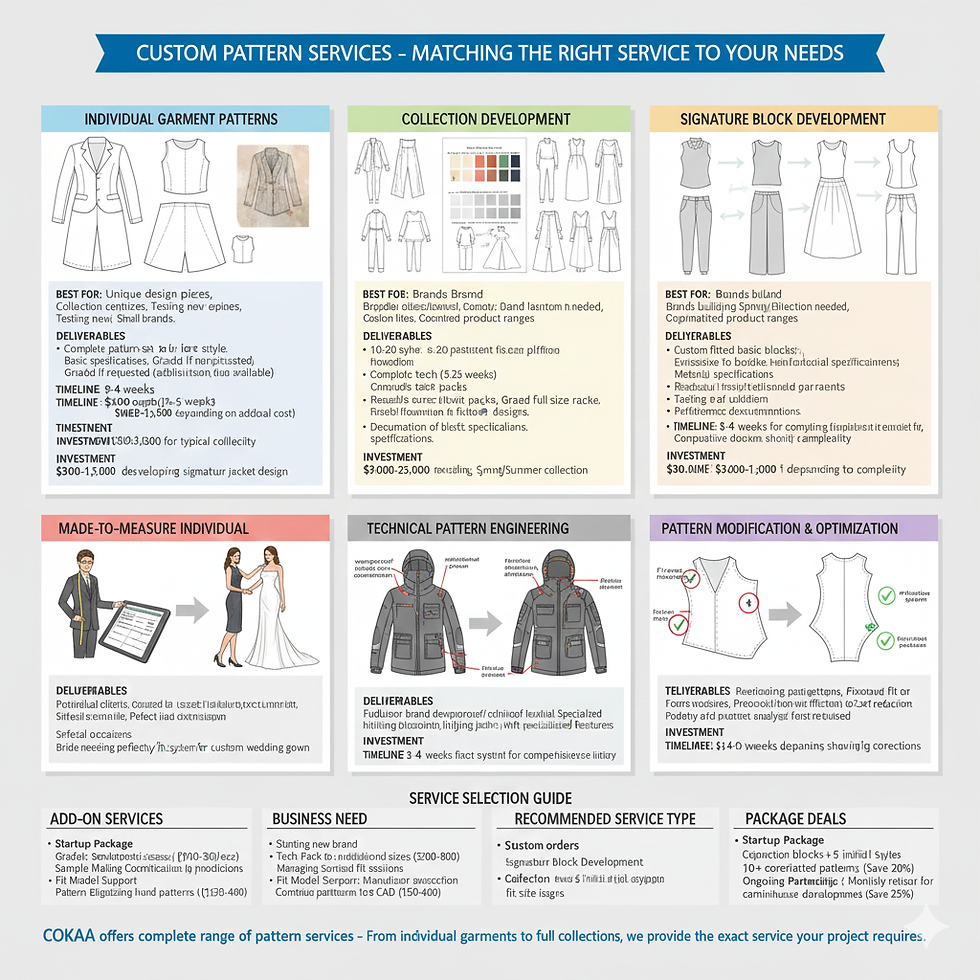

Individual Garment Pattern Development

Best For:

Unique design pieces

Collection centerpiece items

Specialty garments

Test concepts before full line

What You Receive:

Single garment pattern set

Graded if requested

Basic specifications

Sample coordination available

Timeline: 2-4 weeks depending on complexity

Investment: $300-1,500 per garment pattern

Complete Collection Pattern Development

Best For:

Seasonal collections

Brand launches

Coordinated product lines

Fashion brands needing multiple styles

What You Receive:

Multiple coordinated patterns

Consistent fit across collection

Complete technical packages

Size range grading

Production specifications

Timeline: 6-12 weeks for typical collection (10-20 pieces)

Investment: $5,000-25,000 depending on collection size and complexity

Signature Block Development

Best For:

Brands building foundation

Companies needing consistent fit platform

Manufacturers with ongoing production

Designers wanting proprietary blocks

What You Receive:

Custom-fitted basic blocks (bodice, sleeve, skirt, pants)

Engineered to your target customer

Foundation for future designs

Graded across size range

Reusable for multiple styles

Timeline: 4-8 weeks for complete block system

Investment: $2,000-8,000 for comprehensive block library

Made-to-Measure Individual Patterns

Best For:

Individual clients

Custom tailoring businesses

Unique body requirements

Perfect fit priority

What You Receive:

Pattern created to individual measurements

Single-size specific pattern

Fitted to exact specifications

Personal adjustments incorporated

Timeline: 1-3 weeks after measurements received

Investment: $200-800 per individual garment pattern

Technical Pattern Engineering

Best For:

Performance wear

Technical outdoor gear

Specialized functional garments

Products with specific engineering requirements

What You Receive:

Patterns engineered for function

Technical specifications extensive

Testing and refinement included

Material-specific optimization

Performance validation

Timeline: 8-16 weeks for complex technical development

Investment: $3,000-15,000 depending on complexity

Pattern Modification and Optimization

Best For:

Improving existing patterns

Fit problems solving

Production efficiency enhancement

Cost reduction through engineering

What You Receive:

Revised patterns addressing issues

Improved fit or construction

Cost analysis if requested

Comparative documentation

Timeline: 2-4 weeks depending on extent of changes

Investment: $200-1,000 per pattern modified

Part 4: Quality Standards in Custom Pattern Making

Professional patterns meet specific criteria distinguishing them from amateur work.

Accuracy and Precision

Measurement Accuracy: Professional standards require:

±2mm tolerance for critical dimensions

Consistent measurements across all pattern pieces

Verified before delivery

Digital precision in CAD patterns

Geometric Precision: Pattern quality indicators:

Smooth, fair curves (no bumps or flat spots)

Symmetry where intended

Proper grain alignment

Balanced pattern pieces

Corner angles appropriate for construction

Comprehensive Markings

Essential Notations: Professional patterns include:

Grainline arrows clearly marked

Notches for matching points (numbered or coded)

Placement marks for details (pockets, buttons, etc.)

Seam allowances indicated

Pattern piece names and numbers

Size clearly marked

"Cut on fold" indicated where applicable

Directional fabric considerations noted

Construction Information: Patterns should indicate:

Seam types recommended

Ease amounts where relevant

Stretch direction if applicable

Interfacing requirements

Special handling needed

Grading Quality

Proportional Grading: Professional grade maintains:

Proper proportional changes between sizes

Consistent fit intent across range

Appropriate increments (typically 4-5cm between sizes)

Verified measurements for each size

No mathematical errors

Grade Rule Appropriateness: Different body areas grade differently:

Not uniform scaling

Length vs. width grade ratios appropriate

Target demographic considerations

Realistic body proportion changes

Technical Viability

Construction Feasibility: Patterns must be:

Actually sewable (pieces fit together correctly)

Efficient for production

Appropriate for intended construction method

Notched for accurate assembly

Seam allowances suitable for technique

Fabric Compatibility: Pattern engineering considers:

Fabric weight and drape

Stretch properties if knit

Grain line for optimal performance

Bias considerations if present

Lining compatibility if lined

Part 5: Working with a Custom Pattern Making Service

Maximizing value from the relationship requires good communication.

Preparing for Your Pattern Project

Information to Provide:

Design Documentation:

Sketches (multiple views preferred)

Technical flats if available

Reference images showing desired fit

Mood boards for aesthetic context

Fabric swatches or specifications

Fit Information:

Target customer body measurements

Fit preference (close, relaxed, oversized, etc.)

Ease allowances if you have preferences

Problem areas to address

Body type considerations

Technical Requirements:

Size range needed

Production method (cut-and-sew, whole garment, etc.)

Volume expectations

Cost targets if relevant

Timeline requirements

Common Mistakes to Avoid:

Insufficient Information:

Vague fit descriptions ("make it fitted")

No fabric specifications

Unclear size range requirements

Missing critical measurements

No construction method indicated

Unrealistic Expectations:

Expecting immediate turnaround

Assuming first sample will be perfect

Not budgeting for iterations

Underestimating complexity

Expecting lowest price with highest quality

Poor Communication:

Not responding to clarification questions

Changing requirements mid-project

Not providing feedback after fitting

Unclear approval process

No decision-maker identified

Evaluating Pattern Making Services

Questions to Ask:

Experience and Expertise:

How long in business?

What garment categories specialize in?

Do they have experience with your product type?

Can they provide portfolio examples?

Do they understand your target market?

Process and Timeline:

What's the typical process?

How many fitting iterations included?

What's realistic timeline for your project?

What causes delays?

How do they handle revisions?

Deliverables:

What exactly will you receive?

What file formats provided?

Is grading included or additional?

What documentation comes with patterns?

Do they keep archives of your patterns?

Quality Assurance:

How do they verify pattern accuracy?

What happens if there's an error?

Do they test patterns before delivery?

What guarantees do they offer?

How do they handle problems?

Pricing Structure:

How do they price projects?

What's included in base price?

What costs extra (fittings, revisions, grading)?

Payment terms and schedule?

Any ongoing costs?

Red Flags to Watch For

Warning Signs:

Promises unrealistically fast turnaround

Significantly cheaper than market rates

Poor communication or slow responses

No fitting or revision process

Can't provide examples or references

Doesn't ask detailed questions about your needs

Unclear about deliverables

No formal agreement or contract

Unwilling to discuss potential challenges

Overpromises perfection first time

Part 6: Cost Considerations and Pricing

Understanding what influences custom pattern making investment.

Factors Affecting Pattern Making Costs

Garment Complexity: Simple vs. complex dramatically affects price:

Basic t-shirt: $300-600

Simple dress: $500-1,000

Tailored jacket: $1,200-2,500

Technical outerwear: $2,000-4,000

Complexity Factors:

Number of pattern pieces

Curved seaming vs. straight

Details and embellishments

Construction difficulty

Fit precision required

Size Range: More sizes = higher cost:

Single size: Base price

5-size range: +30-50% typically

10+ sizes: +60-100%

Custom size range: Variable

Fitting Iterations: Most services include limited fittings:

First fitting usually included

Second fitting often included

Additional fittings charged separately ($200-500 each)

Extensive revisions may incur fees

Technical Requirements: Specialized needs increase investment:

Performance fabric engineering

Technical specifications extensive

Testing and validation

Specialized construction methods

Regulatory compliance (workwear, PPE)

Documentation Level: More comprehensive specifications cost more:

Basic pattern: Patterns only

Standard: Patterns + basic specs

Complete: Full technical package with construction details, measurement charts, quality standards

Rush Fees: Expedited service commands premium:

Normal timeline: Standard pricing

Rush (50% time reduction): +30-50%

Extreme rush: +50-100%

Typical Pricing Ranges

By Garment Type:

Tops:

Basic tee: $300-600

Fitted blouse: $500-900

Jacket/blazer: $1,200-2,500

Coat: $1,500-3,500

Bottoms:

Basic skirt: $400-800

Pants/trousers: $600-1,200

Jeans (complex): $800-1,500

Dresses:

Simple shift: $600-1,000

Fitted dress: $800-1,500

Evening gown: $1,200-3,000

Specialty:

Swimwear: $800-1,800

Activewear: $700-1,500

Lingerie: $600-1,400

Children's: $300-800

By Service Type:

Per-Garment Custom Patterns: $300-3,000 depending on complexity

Collection Development: $5,000-25,000 for typical 10-20 piece collection

Signature Block Development: $2,000-8,000 for comprehensive system

Pattern Modification: $200-1,000 per pattern

Grading Services: $100-300 per size per garment

Value Assessment

What You're Paying For:

Expertise:

Years of training and experience

Understanding of fit, construction, and design

Problem-solving capabilities

Industry knowledge

Time Investment:

Consultation and planning: 2-4 hours

Pattern drafting: 4-12 hours

Sample coordination: 2-4 hours

Fitting and adjustments: 2-6 hours

Grading: 2-4 hours per size

Documentation: 2-4 hours

Equipment and Overhead:

CAD software ($3,000-10,000 annually)

Professional workspace

Tools and supplies

Insurance and business costs

Quality Assurance:

Verification and checking

Testing when needed

Revision work

Professional standards

Long-Term Value: Quality patterns deliver:

Better-fitting products (higher customer satisfaction)

Reduced returns and complaints

Faster production (clear specifications)

Consistency across production runs

Foundation for future designs

Professional credibility

Part 7: Timeline Expectations

Understanding realistic timeframes prevents frustration.

Typical Project Timelines

Simple Garment (Basic Top/Skirt):

Consultation: 1 week

Pattern draft: 1-2 weeks

Sample and fitting: 1 week

Revisions: 1 week

Total: 4-6 weeks

Moderate Complexity (Dress, Pants, Structured Top):

Consultation: 1 week

Pattern draft: 2-3 weeks

Sample and fitting: 1-2 weeks

Revisions: 1-2 weeks

Grading: 1 week

Total: 6-10 weeks

Complex Garment (Jacket, Coat, Technical Wear):

Consultation: 1-2 weeks

Pattern draft: 3-4 weeks

Sample and fitting: 2 weeks

Revisions (often multiple): 2-4 weeks

Grading: 1-2 weeks

Total: 10-16 weeks

Collection Development:

Initial consultation and planning: 2-3 weeks

Pattern development (staggered): 8-12 weeks

Sample production and fittings: 4-6 weeks

Revisions and finalization: 2-4 weeks

Total: 16-25 weeks (4-6 months)

Factors Affecting Timeline

Your Response Time: Pattern maker can't proceed without:

Approval of initial drafts

Feedback after fittings

Decisions on alternatives

Final approval

Sample Production Time: Not usually pattern maker's control:

Sample maker availability

Fabric procurement

Construction complexity

Shipping if remote

Fitting Logistics: Can extend timeline significantly:

Scheduling fit model or recipient

Multiple stakeholder approvals

Long-distance coordination

Multiple iteration needs

Pattern Maker Workload: Busy seasons affect availability:

Peak times (pre-fashion week)

Current project queue

Team size and capacity

Expediting Options

Rush Service Availability: Many pattern makers offer faster turnaround:

Premium pricing (30-100% upcharge)

Limited to less complex projects

May require scheduling flexibility

Not always available

What Can't Be Rushed: Some aspects have minimum times:

Fabric procurement for samples

Proper fitting evaluation (can't rush judgment)

Drying time if traditional pattern making

Shipping and logistics

Part 8: Digital vs. Traditional Pattern Making

Understanding the methods affects your experience.

Computer-Aided Design (CAD) Pattern Making

Advantages:

Precision:

Exact measurements to fractions of millimeter

Perfect curves and symmetry

Mathematical accuracy in grading

Consistent reproduction

Efficiency:

Faster modifications

Easy grading

Digital storage and archiving

Quick duplication

Flexibility:

Easy to test variations

Simple to make adjustments

Can generate multiple size ranges quickly

Export in various formats

Modern Standard:

Industry standard globally

Production facilities expect digital patterns

Essential for overseas manufacturing

Required for automated cutting

Limitations:

Requires specialized software

Learning curve for complex systems

Technology investment

Can feel less "hands-on"

Traditional Hand-Drafting

Advantages:

Tactile Understanding:

Direct feel for proportions

Traditional craftsmanship

Some pattern makers prefer for creative process

Teaching method for learning

No Technology Dependence:

Works anywhere

No software crashes

No file format issues

Timeless method

Limitations:

Time-consuming modifications

Manual grading labor-intensive

Storage of physical patterns challenging

Digitization needed for production

Human error more likely

Harder to share remotely

COKAA Approach

We use professional CAD pattern making for:

Precision and accuracy

Efficient revisions and grading

Digital file delivery

Industry-standard formats

Long-term archival

While maintaining:

Hands-on understanding of fit and construction

Traditional pattern making expertise

Ability to work from hand-draped designs

Hybrid approach when beneficial

Part 9: Common Challenges and How to Overcome Them

Understanding potential obstacles helps navigate the process smoothly.

Challenge: Miscommunication About Fit

Problem: "Fitted" means different things to different people. Client expects one fit, receives another.

Solution:

Use reference garments (send examples)

Provide specific ease measurements

Show fit examples on similar body types

Be specific about where garment should hit body

Communicate using measurements, not subjective terms

Challenge: Fabric Availability or Changes

Problem: Specified fabric unavailable or client changes fabric after pattern complete, requiring adjustments.

Solution:

Provide fabric swatches early

Verify availability before pattern finalization

Understand that different fabrics may need pattern adjustments

Test with actual production fabric when possible

Inform pattern maker immediately if fabric changes

Challenge: Design Isn't Technically Feasible as Imagined

Problem: Sketch looks great but can't be constructed as drawn, or would be prohibitively expensive.

Solution:

Early technical consultation

Be open to alternatives achieving similar effect

Understand construction limitations

Prioritize which elements are non-negotiable

Trust pattern maker's suggestions

Challenge: Multiple Decision Makers

Problem: Pattern approved by one person, rejected by another. Endless revisions from conflicting feedback.

Solution:

Designate single approval authority

Include all stakeholders in fitting sessions

Get consensus before committing to changes

Document all decisions

Limit revision rounds contractually

Challenge: Budget Constraints

Problem: Project scope exceeds budget, forcing compromises.

Solution:

Discuss budget upfront honestly

Prioritize which garments most critical

Consider phased development

Ask for cost-effective alternatives

Understand where cutting corners has consequences

Challenge: Timeline Pressure

Problem: Production deadline looming, pattern development takes longer than anticipated.

Solution:

Start pattern development early (don't wait until last minute)

Build buffer time into production schedule

Be realistic about iteration needs

Communicate deadline pressures upfront

Be prepared to pay rush fees if necessary

Part 10: Maximizing Your Custom Pattern Investment

Getting the most value from professional pattern services.

Maintain Long-Term Relationship

Benefits of Ongoing Partnership:

Pattern maker learns your aesthetic

Understands your target customer

Knows your quality standards

Faster turnaround on future projects

Better pricing for repeat business

Consistency across collections

Archive and Document Everything

What to Keep:

All pattern files (multiple backups)

Technical specifications

Measurement charts

Sample photos from fittings

Notes on adjustments made

Production feedback

Why It Matters:

Foundation for future designs

Troubleshooting production issues

Training new manufacturers

Protecting your intellectual property

Reference for consistency

Provide Production Feedback

Close the Loop: Inform your pattern maker about:

How patterns performed in production

Any fit issues from customers

Construction challenges encountered

Successful elements to repeat

Changes needed for next season

Benefits:

Continuous improvement

Pattern maker learns from real results

Better patterns in future

Demonstrates professionalism

Strengthens relationship

Understand What You Own

Pattern Ownership: Clarify upfront:

Do you own the patterns? (Usually yes after payment)

Can you use patterns with other manufacturers? (Usually yes)

Does pattern maker keep copies? (Usually yes for their records)

Can pattern maker showcase work? (Discuss confidentiality)

Intellectual Property:

Patterns are typically work-for-hire (you own them)

Get written agreement on ownership

Protect your proprietary designs

Respect pattern maker's process expertise

Conclusion

Custom pattern making services deliver more than just technical drawings—they provide the foundation for your entire garment production, determining fit, quality, consistency, and ultimately customer satisfaction. Professional bespoke pattern development transforms design concepts into production-ready specifications, solving fit challenges, optimizing construction, and ensuring your garments perform as intended.

At COKAA by JR Corporation, our custom pattern making services combine 20 years of expertise with modern technology and deep understanding of garment engineering. We create made-to-measure patterns that translate your design vision into perfectly fitting, production-ready garments, whether you're launching a fashion brand, developing a signature collection, or creating specialized products requiring expert pattern development.

Successful custom pattern making requires clear communication, realistic expectations, appropriate investment, and partnership with experienced professionals who understand not just pattern drafting but comprehensive garment engineering. Brands investing in quality custom pattern services build foundations for superior products, satisfied customers, and long-term business success in competitive fashion markets.

Ready to develop custom patterns for your fashion brand? Contact COKAA for professional bespoke pattern making services tailored to your exact requirements.

Frequently Asked Questions

How long does custom pattern making take?

Timeline depends on complexity: simple garments 4-6 weeks, moderate complexity 6-10 weeks, complex items 10-16 weeks, full collections 4-6 months. Factors include design complexity, fitting iterations needed, grading requirements, and your response time to approvals and feedback.

What information do I need to provide for custom patterns?

Essential information includes: design sketches/technical flats, target body measurements or customer demographics, fabric specifications, size range needed, fit preferences, production method, timeline requirements, and budget. More complete information enables better, faster pattern development.

How much does custom pattern making cost?

Pricing varies by complexity: basic garments $300-600, moderate complexity $500-1,500, complex garments $1,200-4,000+. Collection development $5,000-25,000. Factors affecting cost include garment complexity, size range, fitting iterations, technical requirements, documentation level, and timeline.

What's the difference between modifying existing patterns vs. custom patterns?

Modified patterns adapt existing blocks to new designs—faster and less expensive but limited by original block. Custom patterns are created specifically for your design—optimized for exact fit, fabric, and construction requirements. Custom patterns deliver superior results for unique designs or precise fit needs.

Do I own the patterns after paying for custom pattern making?

Typically yes—custom pattern making is usually work-for-hire, meaning you own the patterns after payment. However, get written agreement clarifying ownership, usage rights, pattern maker's archival rights, and confidentiality. Most pattern makers keep copies for their records but you control usage.

Can custom patterns be used with any manufacturer?

Yes, professional custom patterns are production-ready and can be used with any manufacturer capable of your garment type. Digital pattern files in industry-standard formats (DXF, AAMA, etc.) ensure compatibility with most production facilities globally, giving you manufacturing flexibility.

Comments