How AI is Changing Pattern Making: The Future of Fashion Design

- thecottonkraftco

- Dec 15, 2025

- 9 min read

The AI Revolution in Pattern Making: Hype vs. Reality

Artificial Intelligence promises to transform every industry, and fashion pattern making is no exception. Headlines tout AI systems that "instantly generate perfect patterns from sketches," algorithms that "eliminate pattern making errors," and machine learning that "replaces years of expertise with automation." But what's real capability versus marketing hype? How is AI actually changing pattern making today, and what does the future genuinely hold?

At COKAA by JR Corporation, our 20 years of pattern making expertise positions us uniquely to evaluate AI's true impact on our industry. We've tested emerging AI tools, implemented beneficial technologies where appropriate, and maintained perspective on what AI can and cannot do. This comprehensive guide separates reality from speculation, revealing how AI is genuinely transforming pattern making while explaining why human expertise remains irreplaceable.

Whether you're a fashion brand considering AI pattern tools, a pattern maker wondering about job security, or an industry observer curious about technology's impact on fashion, you'll discover exactly where AI adds value, where it falls short, and how the most successful approach combines artificial intelligence with human creativity and technical expertise.

Part 1: Current AI Applications in Pattern Making

AI already enhances various pattern making processes, though not always in ways marketing suggests.

AI-Assisted Pattern Grading

How It Works: Machine learning algorithms analyze thousands of graded pattern sets, learning relationships between base sizes and graded sizes across body regions.

Current Capabilities:

Suggests grade rules based on historical data

Identifies inconsistent grading across pattern sets

Automates repetitive grading calculations

Validates grade rules against body measurement databases

Limitations:

Requires extensive training data from skilled pattern makers

Cannot create grading rules for novel garment types

Struggles with unconventional designs outside training data

Still requires human verification and adjustment

COKAA Perspective: AI grading tools accelerate our pattern grading and marking service but don't replace expertise. We use AI suggestions as starting points, then apply 20 years of knowledge ensuring graded patterns maintain design integrity and fit quality across sizes.

Automated Measurement Extraction

How It Works: Computer vision AI analyzes garment images or 3D scans, automatically extracting measurements without manual measurement.

Current Capabilities:

Measures visible dimensions from photographs

Extracts body measurements from 3D scans

Identifies key measurement points automatically

Generates measurement specification sheets

Limitations:

Accuracy depends on image quality and angles

Cannot measure internal construction details

Struggles with complex draping or loose fits

Requires verification against actual garments

Real-World Application: Useful for quick preliminary measurements but not production-grade accuracy. Our sample to pattern service uses AI measurement as initial estimation, then manual verification ensures precision.

AI-Powered Pattern Digitization

How It Works: Image recognition AI converts scanned pattern images to digital CAD files through automatic edge detection and tracing.

Current Capabilities:

Automatically detects pattern piece outlines

Identifies and labels common pattern markings

Converts raster images to vector CAD files

Speeds initial digitization phase

Limitations:

Struggles with damaged or unclear patterns

Often mis-identifies complex markings

Creates segmented lines rather than smooth curves

Requires extensive manual cleanup

COKAA Implementation: We use AI digitization for initial trace capture, then skilled pattern makers refine curves, verify measurements, and complete technical specifications. This hybrid approach combines AI speed with human accuracy.

Intelligent Pattern Optimization

How It Works: AI algorithms analyze pattern layouts, suggesting modifications improving fabric efficiency, ease of construction, or fit quality.

Current Capabilities:

Optimizes marker layouts minimizing fabric waste

Suggests seam placement improvements

Identifies potential construction problems

Recommends efficiency enhancements

Limitations:

Cannot understand design intent or aesthetic goals

May suggest technically efficient but visually unappealing changes

Lacks understanding of fabric behavior nuances

Requires pattern maker judgment on recommendations

Part 2: Emerging AI Pattern Generation Technologies

Experimental AI systems attempt more ambitious pattern creation, with varying success.

Sketch-to-Pattern AI

The Promise: Upload fashion sketch, AI generates production-ready patterns automatically.

Current Reality: Early-stage technology producing rough pattern approximations requiring substantial refinement.

How It Works:

Computer vision identifies garment elements in sketches

Machine learning matches design elements to pattern blocks

AI assembles pattern pieces approximating sketch

Outputs basic pattern draft

Limitations:

Cannot interpret complex design details

Produces generic patterns lacking fit precision

Misinterprets artistic sketch elements

Requires extensive manual correction

Industry Assessment: Years away from replacing professional pattern makers. Current systems useful for concept exploration or inspiration, not production patterns.

AI Fit Prediction

The Promise: AI predicts how patterns will fit bodies, suggesting adjustments before physical sampling.

Current Reality: Useful assistance but far from replacing fit testing.

How It Works:

Analyzes pattern measurements vs. body measurements

Compares to database of fit-tested patterns

Identifies likely fit issues (tightness, gaping, etc.)

Suggests pattern modifications

Limitations:

Cannot account for fabric drape and behavior

Struggles with novel designs outside training data

Fit preferences subjective (AI learns preferences slowly)

False positives and negatives common

Practical Use: Helpful early-warning system flagging obvious problems, but physical or 3D virtual fit testing remains essential.

Generative Design AI

The Promise: AI generates pattern variations exploring design possibilities within specified parameters.

Current Reality: Interesting for inspiration, rarely production-ready without modification.

How It Works:

Designer sets constraints (garment type, silhouette, features)

AI generates multiple pattern variations

Designer selects preferred options

Selected patterns refined for production

Limitations:

Generated patterns often technically unfeasible

Aesthetic quality inconsistent

Lacks understanding of construction methods

Requires significant human curation

Creative Application: Useful brainstorming tool suggesting unexpected design directions, not autonomous designer replacement.

Part 3: AI's Impact on Pattern Making Workflow

AI changes how pattern makers work rather than replacing them entirely.

Augmented Pattern Making

Human-AI Collaboration: Most effective approach combines strengths of both:

AI handles repetitive calculations and measurements

Humans make creative and technical decisions

AI suggests options, humans choose and refine

Humans verify AI outputs ensuring quality

Workflow Integration: Modern pattern makers use AI tools alongside traditional methods:

AI accelerates initial drafting

Humans refine for accuracy and aesthetics

AI checks for mathematical errors

Humans ensure design intent maintained

Skill Evolution

New Competencies: Pattern makers need evolving skill sets:

Understanding AI tool capabilities and limitations

Prompt engineering (giving AI effective instructions)

AI output evaluation and correction

Hybrid workflow optimization

Enduring Skills: Core pattern making expertise remains essential:

Garment construction knowledge

Fit analysis and problem-solving

Fabric behavior understanding

Design interpretation

Quality assessment

COKAA Approach: We invest in both AI tools and pattern maker training, ensuring our team leverages technology while maintaining craftsmanship standards that 20 years of experience built.

Part 4: Benefits of AI in Pattern Making

When applied appropriately, AI delivers tangible advantages.

Speed and Efficiency

Accelerated Repetitive Tasks:

Pattern grading: 50-70% faster with AI assistance

Measurement extraction: Preliminary data in minutes vs. hours

Marker optimization: Instant rather than manual trial-and-error

Pattern variations: Rapid exploration of options

Time Savings Allocation: Time saved on routine tasks redirected to:

Creative design development

Complex problem-solving

Client consultation

Quality refinement

Consistency and Error Reduction

Mathematical Precision: AI excels at calculations:

Grade rule application without human arithmetic errors

Measurement consistency across pattern sets

Seam length matching verification

Symmetry checking

Pattern Validation: AI catches common mistakes:

Mismatched seam lengths

Incorrect seam allowances

Missing notches or markings

Measurement discrepancies

Data-Driven Insights

Pattern Performance Analytics: AI analyzes pattern databases:

Identifies successful patterns for specific body types

Reveals common fit issues across styles

Suggests improvements based on historical data

Tracks pattern evolution and refinements

Cost Reduction

Efficiency Economics:

Reduced pattern development time lowers costs

Fewer sampling iterations through better fit prediction

Optimized markers reduce fabric waste

Automation handles routine work at lower cost

Part 5: Limitations and Challenges of AI Pattern Making

Understanding AI's limitations prevents unrealistic expectations and poor decisions.

Cannot Replace Human Judgment

Creative Decisions: AI cannot make aesthetic choices:

Design appeal and style

Brand identity appropriateness

Fashion trend interpretation

Creative problem-solving

Technical Judgment: Complex decisions require human expertise:

Fabric-specific pattern adjustments

Construction method selection

Fit philosophy interpretation

Quality vs. cost trade-offs

Lack of Contextual Understanding

Design Intent: AI doesn't understand "why":

Cannot interpret designer's vision

Misses subtle design nuances

Doesn't grasp brand aesthetic

Cannot balance competing priorities

Manufacturing Reality: AI lacks production knowledge:

Factory capability limitations

Available equipment constraints

Skill level requirements

Cost implications of suggestions

Data Dependency and Bias

Training Data Requirements: AI only knows what it's taught:

Requires vast high-quality data sets

Limited by available training examples

Biased toward common garment types

Struggles with innovative designs

Historical Bias: AI perpetuates existing biases:

Size range limitations from historical data

Body type representation gaps

Cultural and regional biases

Gender assumptions in patterns

Technology Limitations

Current Constraints:

Cannot physically touch fabrics

No understanding of drape and movement

Cannot perform fit testing

Lacks real-world garment experience

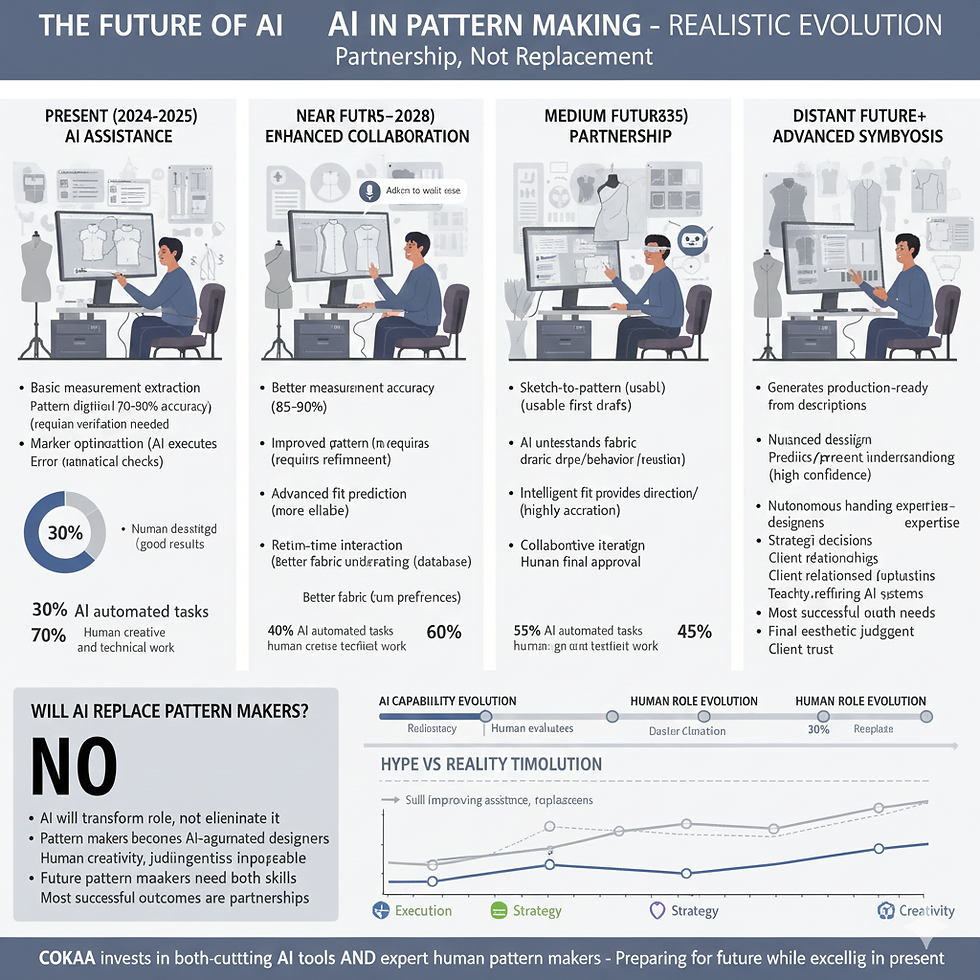

Part 6: The Future of AI in Pattern Making

Realistic future outlook based on technology trajectory and industry needs.

Near-Term Evolution (1-3 Years)

Improving Existing Tools:

More accurate measurement extraction

Better pattern digitization

Enhanced grading suggestions

Improved fit prediction

Wider Adoption:

AI tools becoming standard in pattern software

More pattern makers trained in AI assistance

Integration into design and production workflows

Cost reduction making tools accessible to smaller brands

Medium-Term Developments (3-7 Years)

Advanced Capabilities:

Sketch-to-pattern improving substantially

AI understanding fabric properties better

More sophisticated fit prediction

Generative design producing usable patterns

Workflow Integration:

Seamless AI integration across design-to-production pipeline

Real-time collaboration between designers and AI

Automated quality control throughout process

Pattern libraries with AI-powered search and customization

Long-Term Possibilities (7+ Years)

Potential Breakthroughs:

AI understanding design intent from natural language

Virtual AI pattern making assistants

Fully automated routine pattern development

AI-human collaboration achieving superhuman results

Realistic Expectations: Even with major advances, human expertise will remain essential for:

Creative vision and design direction

Complex problem-solving

Quality assessment

Client relationships and consultation

Part 7: Implementing AI in Your Pattern Making Process

Practical guidance for brands considering AI tools.

Assessing Your Needs

Questions to Answer:

What pattern making challenges do we face?

Which tasks are most repetitive or time-consuming?

Where do we struggle with consistency?

What would provide most value: speed, accuracy, or cost reduction?

AI Suitability: AI works best for:

High-volume repetitive work

Standard garment types

Tasks requiring mathematical precision

Pattern optimization and validation

AI less suitable for:

Highly creative custom work

Novel garment types

Complex problem-solving

Brand-specific aesthetic decisions

Choosing AI Tools

Evaluation Criteria:

Actual capabilities vs. marketing claims

Integration with existing systems

Learning curve and training requirements

Cost vs. benefit analysis

Vendor support and updates

Trial and Testing:

Request demonstrations

Test on real projects

Compare AI outputs to manual methods

Assess quality and time savings

Calculate realistic ROI

Hybrid Approach

Best Practice: Combine AI assistance with human expertise:

Use AI for speed on routine tasks

Apply human judgment to AI suggestions

Verify AI outputs before production

Maintain human oversight throughout

COKAA Model: Our custom pattern making service leverages AI where beneficial while ensuring every pattern receives expert human review, refinement, and quality assurance—delivering both efficiency and excellence.

Conclusion: AI as Tool, Not Replacement

Artificial Intelligence is genuinely transforming pattern making—accelerating routine tasks, catching errors, optimizing layouts, and suggesting improvements. These capabilities deliver real value: faster development cycles, more consistent quality, reduced costs, and freed capacity for creative work. AI will continue improving, expanding capabilities and integration depth.

However, AI is not replacing skilled pattern makers. The fashion industry's most successful approach treats AI as a powerful tool augmenting human expertise rather than autonomous replacement. Pattern making requires creativity, technical judgment, contextual understanding, and quality assessment that current (and foreseeable) AI cannot provide.

At COKAA by JR Corporation, 20 years of pattern making expertise informs our AI integration philosophy: embrace beneficial technology while maintaining the human craftsmanship, design sensitivity, and technical mastery that AI cannot replicate. Our clients benefit from AI efficiency combined with expert refinement—patterns developed faster without compromising the quality, accuracy, and design integrity that professional pattern making demands.

The future of pattern making isn't human versus AI—it's humans empowered by AI achieving results neither could accomplish alone. That future is already here for brands choosing pattern making services that thoughtfully integrate technology with irreplaceable expertise.

Ready for pattern making combining AI efficiency with human excellence? Contact COKAA for intelligent pattern services delivering the best of both worlds.

Frequently Asked Questions About AI Pattern Making

Will AI replace pattern makers?

No. AI handles specific tasks well (calculations, optimization, measurement extraction) but cannot replace human creativity, design interpretation, technical judgment, fabric understanding, or quality assessment. AI augments pattern makers' capabilities rather than replacing them entirely.

Are AI-generated patterns production-ready?

Current AI pattern generation produces rough approximations requiring substantial human refinement before production use. AI assists pattern development but doesn't create finished production patterns autonomously.

How accurate is AI pattern grading?

AI grading suggestions are generally mathematically accurate but require human verification ensuring proportions, aesthetics, and fit quality maintain across sizes. AI accelerates grading but skilled pattern makers must validate results.

Can AI understand my design vision?

No. AI cannot interpret creative intent, brand aesthetic, or design philosophy. Pattern makers translate your vision into patterns while AI assists with technical execution.

Is AI pattern making expensive?

Costs vary widely. Some CAD software includes basic AI features at no extra cost. Specialized AI tools range from affordable subscriptions to enterprise licensing. ROI depends on usage volume and application suitability.

Should small brands use AI pattern tools?

Depends on needs. High-volume standard production benefits most. Small-batch custom work sees less benefit. Many small brands get better value partnering with pattern making services that leverage AI on their behalf rather than investing in tools directly.

Comments